FIRE RATED GLASS

Fire rated glass applications are on high demand due to the forever changing building and safety regulations in commercial and public environments. (See Approved Document B) To help our customers understand this product a little bit better, we need to start with the basics.

Advanced Fire Protection with High-Performance Glass Solutions

Wide Range

Our extensive selection is engineered to provide superior protection across diverse applications, offering reliable fire resistance without compromising on clarity or design flexibility.

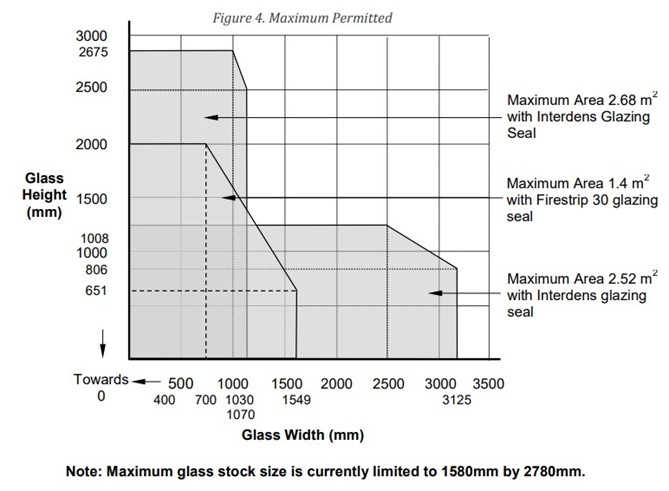

Largest Sizes Available

Our Fire Rated Glass is offered in the largest dimensions, allowing for seamless integration in large-scale projects while maintaining optimal safety and performance.

Design and Specification

We provide expert guidance to help you design fire-rated systems and select the most compatible, cost-effective solutions for your specific needs.

Hybrid Performance

We combine fire-rated glass with other advanced technologies, offering customizable solutions like fire-rated switchable or bullet-resistant glass to meet diverse project requirements.

Areas of usage

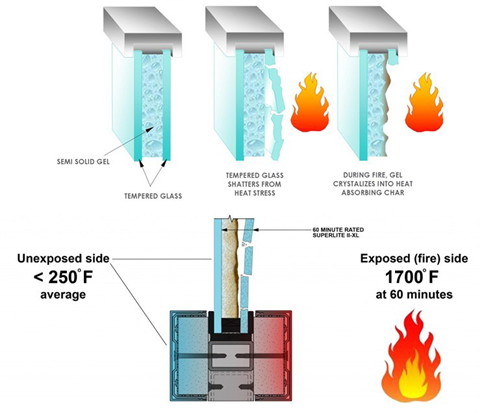

Current legislation permits the use of glass products in building, as glass has many positive attributes in terms of providing a fire-safe building. It is essentially non-combustible and, therefore, complies with all the regulations and requirements for the surface spread of flame. If insulated properly, the glass will not permit smoke to penetrate, nor will it produce smoke during the critical developing phase of a fire. Non-insulated glass rarely fails integrity in the center of the pane, but gaps may develop at the perimeter of the panel. Such gaps are normally associated with the deformation of the glazing system, and intumescent materials can compensate for this by expanding to fill any gaps that start to develop. When intumescent laminate reacts to fire and expands, it changes color from transparent to opaque.

Types of Fire Rated Glass:

Fire rated glass is designed to provide protection against fire by maintaining its integrity and insulation properties for a specified period. There are two main types of fire rated glass:

- Integrity (E): This type of fire rated glass prevents the passage of flames and hot gases but does not provide insulation against heat. It is designed to maintain its structural integrity during a fire, preventing the spread of fire and smoke to adjacent areas.

- Insulation (I): In addition to maintaining its integrity, this type of fire rated glass also provides insulation against heat. It prevents the transfer of radiant and conductive heat, protecting people and property on the non-fire side from the effects of high temperatures.

Radiated Heat and Fire Rating

Radiated heat is a critical factor in fire safety. Fire rated glass with insulation properties (I) is essential in scenarios where the protection of people and sensitive materials from radiant heat is crucial. This type of glass ensures that the temperature on the non-fire side remains at a safe level, reducing the risk of burns and heat-related injuries.Compatibility with Certified Frames

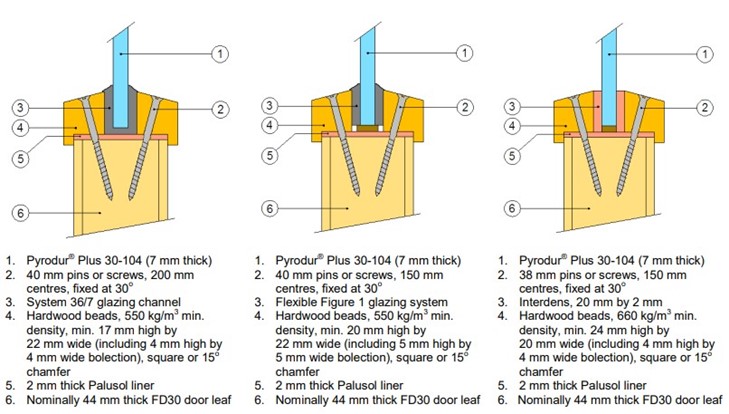

It is vital to study the compatibility between fire rated glass and the certified frame in which it will be installed. The performance of fire rated glass is highly dependent on the frame, as an incompatible frame can compromise the glass’s effectiveness. Certified frames are tested and approved to work with specific types of fire rated glass, ensuring that the entire assembly meets the required fire safety standards.Internal vs. External Applications

Testing and Certification

| ID | Description | Thickness | Frame Material | Frame Application | Integrity/Insulation |

|---|---|---|---|---|---|

| 1 | 7mm Pyrodur Plus 30-104 | 7 | Timber | Doorsets | 30/00 |

| 2 | 7mm Pyrodur Plus 30-104 | 7 | Timber | Screens | 30/00 |

| 3 | 7mm Pyrodur Plus 30-104 | 7 | Timber | Screens | 30/00 |

| 4 | 7mm Pyrodur Plus 30-104 | 7 | Steel | Doorsets | 30/00 |

| 5 | 7mm Pyrodur Plus 30-104 | 7 | Steel | Screens | 30/00 |

| 6 | 7mm Pyrodur Plus 30-104 | 7 | Timber | Doorsets | 30/00 |

| 7 | 7mm Pyrodur Plus 30-104 | 7 | Timber | Screens | 30/00 |

| 8 | 7mm Pyrodur Plus 30-104 | 7 | Composite | Doorsets/DL | 30/00 |

| 9 | 7mm Pyrodur Plus 30-105 | 7 | Composite | Doorsets/SS | 30/00 |

| 10 | 7mm Pyrodur Plus 30-105 | 7 | Timber | Doorsets | 30/00 |

| Thickness | Frame Material | Frame Application | Integrity/Insulation |