Thermally toughened soda lime silicate glass was first manufactured in 1931.

Since that time breakages of thermally toughened glass have occurred.

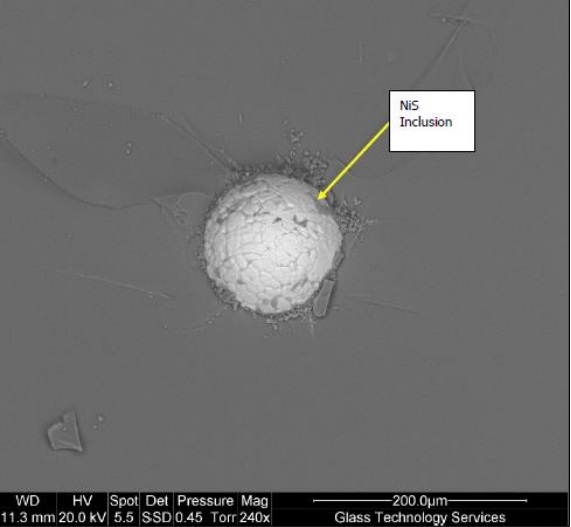

It was in 1961 that E R Ballantyne issued a report on the breakage of thermally toughened cladding

panels from a building in Melbourne, Australia. This report showed that the inclusion of ‘nickel

sulfide’ was at the origin of the fracture. Further work explained that the inclusion experienced a

phase change that caused the toughened glass to fracture.

Thermally treated glasses may fracture from a variety of causes. These in order of occurrence are:

• Edge damage, caused during e.g. manufacture, transportation, installation, service conditions

• Sharp body impact, either accidental or malicious

• Poor glazing design, e.g. glass to metal contact

• Poor workmanship e.g. incorrect installation, inappropriate assembly of fittings, unskilled labor

• Inferior glazing materials, e.g. use of incorrect gaskets, bushes, etc.

• Excessive loads either mechanical or thermal

• Incorrect processing of glass

Inclusions in the glass

Thermally treated glass thus becomes associated with unexplained, but noticeable, breakages and

these have been labeled “spontaneous fractures”, whereas breakages from similar causes in other

types of glass are frequently referred to as “cracks”. In fact, thermally treated glass is less

susceptible to breakages than any other form of glass, but the fracture propagates with a loud noise

which may be accompanied by falling particles, and is therefore much more obvious.

In addition to toughened glass, the origin of the fracture, which is a source of information as to

the cause is often lost. Of the various causes of “spontaneous fracture”, only that associated with

the presence of foreign particles in the glass is more likely to cause a fracture in thermally treated

glass than in other forms of glass, because they can disturb the very high built-in stresses in

thermally treated glass. Spontaneous breakage due to inclusions is possible in any of the three

different types of thermally treated glass products are available:

• Heat strengthened soda lime silicate glass – EN 1863

• Thermally toughened soda lime silicate safety glass – EN 12150

• Heat soaked thermally toughened soda lime silicate safety glass – EN 14179

The presence of inclusion within the annealed glass is not a problem. It is only of concern

when in the tensile stress zone of a thermally treated product.

This article covers the spontaneous breakage of thermally treated glasses, together with types of inclusions, the rate of occurrence, and associated risks.

For the purpose of this article the following definitions apply:

- Spontaneous breakage (also referred to as spontaneous fracture) – An apparent unexplained fracture that can occur in heat-treated glasses without an obvious external influence.

- Inclusions – An inclusion that by virtue of its size and position in the thermally treated glass can cause failure. NOTE: These can be of various materials that are either critical e.g. nickel sulfide, or non-critical e.g. refractory stone, un-melted frit.

- Critical inclusions – An inclusion or small impurity in the glass that can undergo a phase change which may lead to fracture of thermally toughened soda lime silicate glass sometime after toughening. NOTE: Failure is also possible in heat-strengthened soda lime silicate glass.

- Nickel Sulfide inclusions -The most common type of critical inclusion found within thermally treated soda lime silicate glass.

- Level of associated risk – Risk of spontaneous breakage of thermally treated soda lime silicate glass on a statistical basis due to the presence of critical inclusions.